Gel stress toys have become a popular tool for relaxation, focus, and even sensory development. Whether used at home, in offices, or as promotional items, these small toys provide a simple yet effective way to reduce stress. But behind every reliable product is a well-structured Gel Stress Toys Factory. Understanding how such a factory operates can help consumers and business buyers make informed choices.

Production Process: From Material to Finished Toy

A Gel Stress Toys Factory starts with selecting appropriate materials. The outer layer is typically made from a durable, flexible plastic or silicone that can withstand repeated squeezing without tearing. Inside, a non-toxic gel or liquid is carefully measured and inserted to create the satisfying tactile experience.

Quality checks are essential at each step. Factories often have specialized teams to inspect the integrity of the toy's seal, the consistency of the gel, and the overall finish. For businesses looking to order in bulk, understanding the production workflow ensures that products meet safety and durability standards.

Customization and Design Flexibility

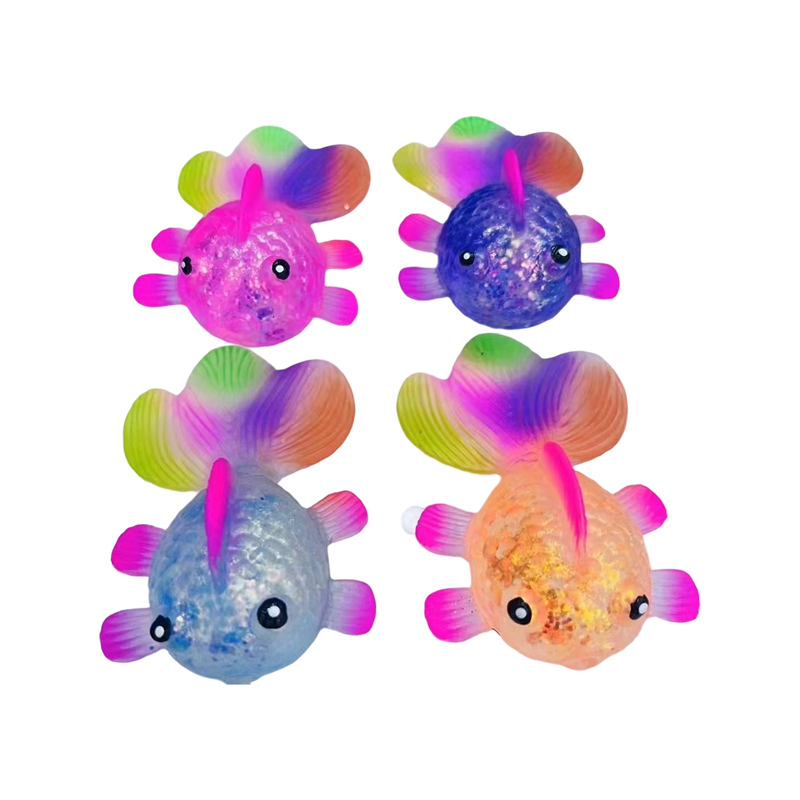

One advantage of working with a Gel Stress Toys Factory is the ability to customize designs. Many factories offer options for different shapes, colors, and branding opportunities. Companies can request logos or special packaging to use the toys as corporate gifts, promotional giveaways, or event merchandise.

For consumers, customization may include selecting a favorite color or shape. Some factories even offer themed designs, such as animals, fruits, or abstract shapes, appealing to children and adults alike.

Safety and Compliance Considerations

Safety is a major concern for both individual buyers and businesses. A reputable Gel Stress Toys Factory adheres to safety guidelines, such as using non-toxic gels, avoiding small detachable parts that could be choking hazards, and meeting regional compliance standards like CE or ASTM.

Regular testing and batch inspections help ensure that each toy is safe for handling. For businesses, this reliability is crucial, as it reduces the risk of product recalls and reinforces consumer trust.

Benefits for Consumers and Businesses

Consumers enjoy the sensory and stress-relief benefits of gel stress toys, while businesses can leverage them as effective promotional tools. By sourcing from a reliable Gel Stress Toys Factory, companies can access large quantities of uniform products, which helps maintain brand consistency.

Additionally, some factories provide guidance on packaging, shipping, and even marketing support. This can simplify the procurement process, particularly for small businesses entering the promotional products market for the first time.

Selecting the Right Gel Stress Toys Factory

When choosing a Gel Stress Toys Factory, consider factors such as production capacity, experience, quality control measures, and customization options. Reading reviews or visiting the factory when possible can offer additional insights into their reliability and service.

Effective communication between the buyer and the factory ensures that expectations are clear and timelines are met. This can make the difference between a smooth supply experience and unexpected challenges.

A Gel Stress Toys Factory plays a crucial role in bringing these simple yet effective products to market. From material selection to customization, safety checks, and large-scale production, the factory's processes ensure both consumers and businesses receive reliable and enjoyable toys. Understanding how a factory operates can help buyers make better decisions, whether they are purchasing a single toy or planning a bulk order for business purposes.

By focusing on quality, safety, and design flexibility, a Gel Stress Toys Factory supports the growing demand for stress-relief products in both personal and commercial markets.