Stress relief toys have become a common item in offices, schools, and homes. Among these, flour-filled stress balls offer a simple, tactile way to reduce tension while providing safe and affordable play. Understanding how a Flour Filled Stress Ball Factory operates can help buyers, distributors, and educators make better decisions when sourcing these products.

Production Process Overview

A Flour Filled Stress Ball Factory begins its process with raw materials that include durable latex or synthetic rubber for the outer shell and finely milled flour for the filling. The shell is carefully shaped and tested for elasticity to ensure it can withstand repeated squeezing without bursting. The flour is then filled to maintain uniform density, giving each stress ball consistent feel and weight.

Attention to filling techniques is crucial. Too much or too little flour affects both the texture and the safety of the ball. Factories that monitor these details can provide products that perform reliably for various users, including children and adults.

Safety and Compliance Considerations

Safety is a primary concern for stress balls. A responsible Flour Filled Stress Ball Factory adheres to testing standards to ensure non-toxic materials, proper sealing, and resistance to accidental bursting. Certifications and quality checks help buyers avoid potential hazards and demonstrate compliance with consumer safety regulations. This makes the products suitable for schools, workplaces, and promotional events.

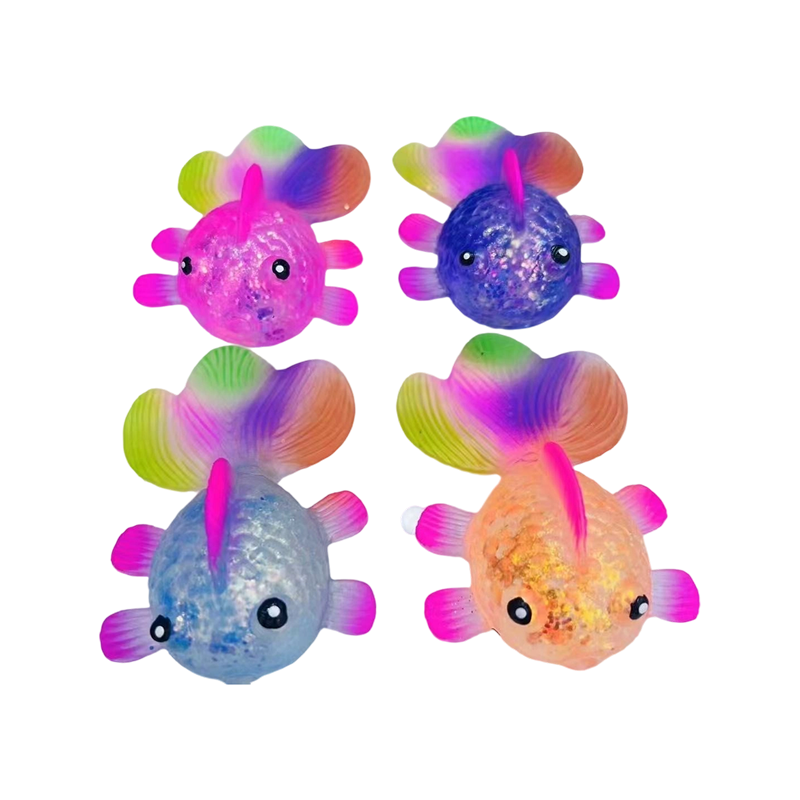

Customization and Design Options

Many buyers seek customization, whether through color, size, or printed logos. A flexible Flour Filled Stress Ball Factory can handle these requests while keeping production consistent. For promotional products, branding adds value, while educational institutions may prefer color-coded or themed balls for classroom activities. Understanding what a factory can adjust in the production process helps buyers plan more effectively.

Production Efficiency and Reliability

Efficiency in a Flour Filled Stress Ball Factory affects cost and delivery schedules. Well-organized factories with precise machinery can produce large quantities without sacrificing quality. Reliable production timelines are particularly important for seasonal campaigns or bulk orders. Clear communication with the factory about lead times and quantities helps avoid delays and ensures smoother logistics.

After-Sales Support

Support from a Flour Filled Stress Ball Factory does not end at shipment. Factories that offer guidance on storage, handling, or minor repairs add practical value. Responsive communication can also resolve concerns quickly, whether for product defects or adjustments in custom orders. This ongoing support is valuable for buyers who intend to maintain long-term partnerships.

Why Understanding the Factory Matters

Visiting or researching a Flour Filled Stress Ball Factory can provide insight into materials, workflow, and quality control procedures. For buyers, seeing the process firsthand or learning about it from reliable sources builds confidence in the products. It also helps clarify expectations for production capacity, customization options, and safety practices.

A Flour Filled Stress Ball Factory plays a key role in producing toys that are safe, consistent, and suitable for a wide range of users. By understanding production methods, safety standards, and customization capabilities, buyers can make informed decisions and choose products that meet their needs. Beyond the product itself, communication and support from the factory ensure smooth operations and reliable supply over time.